Products

Products

Overview:

A gate valve is a type of valve that controls the on-off of fluid by the sliding of a gate (disc) along the vertical direction of the valve seat. Its sealing performance depends on the fit between the gate and the valve seat, and it is widely used in industrial fields such as water supply and drainage, petrochemicals, power, and metallurgy.

Nominal diameter: 10mm - 1000mm and 1/2" - 60"

Nominal pressure: 1.0MPa to 16.0MPa/150Lb to 1500Lb/10K to 160K

Temperature: -196℃ to 700℃

Standards: GB, DIN, API, ANSI, JIS, BS, etc

Body material: carbon steel, stainless steel, alloy steel, ultra-low carbon stainless steel, titanium alloy, high-nickel alloy and Monel alloy, etc

Drive methods: manual, worm gear drive, bevel gear, electric, pneumatic, hydraulic, etc

Overview:

A globe valve is a type of valve that controls fluid flow by lifting and lowering the valve disc (opening and closing member) along the centerline of the valve seat. Its working principle is to use the sealing surface of the valve disc and valve seat to adhere or separate, achieving the cutting, adjustment or throttling of the medium in the pipeline.

Nominal diameter: 10mm~1000mm and 1/2 "~60"

Nominal pressure: 1.0MPa~16.0MPa/150Lb~1500Lb/10K~160K

Temperature: - 196℃~700℃

Standards: GB, DIN, API, ANSI, JIS, BS, etc

Body materials: carbon steel, stainless steel, alloy steel, ultra-low carbon stainless steel, titanium alloy, high nickel alloy, Monel alloy, etc

Drive modes: manual, worm gear transmission, bevel gear, electric, pneumatic, hydraulic, etc

Overview:

A Check Valve, also known as a one-way valve or non-return valve, is a type of valve that controls its opening and closing by the power of the medium flow itself. Its core function is to prevent the backflow of the medium in the pipeline and also to stop the medium from flowing back in the disconnected pipeline, ensuring the safe and stable operation of the system.

Nominal diameter: 10mm - 1000mm and 1/2" - 60"

Nominal pressure: 1.0MPa to 16.0MPa/150Lb to 1500Lb/10K to 160K

Temperature: -196℃ to 700℃

Standards: GB, DIN, API, ANSI, JIS, BS, etc

Body material: carbon steel, stainless steel, alloy steel, ultra-low carbon stainless steel, titanium alloy, high-nickel alloy and Monel alloy, etc

Drive methods: manual, worm gear drive, bevel gear, electric, pneumatic, hydraulic, etc

Overview:

A ball valve is a valve with a spherical opening and closing element, which is driven by a valve stem and rotates around the axis of the ball valve.Ball valves feature a simple structure, reliable sealing and low flow resistance. They are widely used in industrial fields such as petroleum, chemical engineering, natural gas and water treatment, as well as in civil pipeline systems.

Nominal diameter: 10mm - 1000mm and 1/2" - 60"

Nominal pressure: 1.0MPa to 16.0MPa/150Lb to 1500Lb/10K to 160K

Temperature: -196℃ to 700℃

Standards: GB, DIN, API, ANSI, JIS, BS, etc

Body material: carbon steel, stainless steel, alloy steel, ultra low carbon stainless steel, titanium alloy, high nickel alloy and Monel alloy, etc

Drive methods: manual, worm gear drive, bevel gear, electric, pneumatic, hydraulic, etc

Overview:

Butterfly valves, also known as flap valves, are valves that use a circular butterfly plate as the opening and closing part and rotate with the valve stem to achieve opening and closing actions. They are mainly used to cut off, connect and regulate the medium in pipelines.

Nominal diameter: 10mm - 1000mm and 1/2" - 60"

Nominal pressure: 1.0MPa to 16.0MPa/150Lb to 1500Lb/10K to 160K

Temperature: -196℃ to 700℃

Standards: GB, DIN, API, ANSI, JIS, BS, etc

Body material: carbon steel, stainless steel, alloy steel, ultra low carbon stainless steel, titanium alloy, high nickel alloy and Monel alloy, etc

Drive methods: manual, worm gear drive, bevel gear, electric, pneumatic, hydraulic, etc

Overview:

A water valve is a mechanical device used to control the flow of water (or other liquids) in pipelines or systems. By opening, closing or regulating components such as the valve disc and valve core, it achieves on-off control of water flow, flow regulation, pressure control or direction switching. Its core function is to ensure the safe and stable operation of the water supply system and meet the water demand in different scenarios.

Nominal diameter: 10mm - 1000mm and 1/2" - 60"

Nominal pressure: 1.0MPa to 16.0MPa/150Lb to 1500Lb/10K to 160K

Temperature: -196℃ to 700℃

Standards: GB, DIN, API, ANSI, JIS, BS, etc

Body material: carbon steel, stainless steel, alloy steel, ultra low carbon stainless steel, titanium alloy, high nickel alloy and Monel alloy, etc

Drive methods: manual, worm gear drive, bevel gear, electric, pneumatic, hydraulic, etc

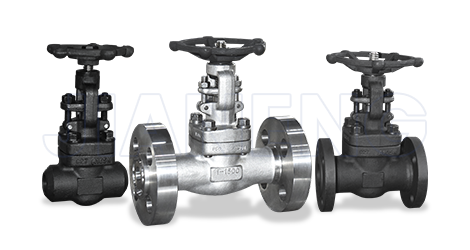

Overview:

Forged steel valves refer to valves whose main components such as the valve body, valve cover and valve core are manufactured by forging process. The core material is high-quality steel (such as carbon steel, stainless steel, alloy steel, etc.). Forged steel valves are widely used in industrial scenarios with high pressure, high temperature, high corrosion or high purity, and are especially indispensable in fields such as petroleum, chemical engineering and power.

Nominal diameter: 1/2" to 4"(DN10mm to DN100mm)

Nominal pressure: 150LB to 4500LB(1.0MPa to 76.0 MPa)

Body material: A105, LF2, F11, F304, F316, F321, etc

Operation methods: manual, pneumatic, electric, hydraulic

Connection methods: Flange, butt welding, socket welding, thread

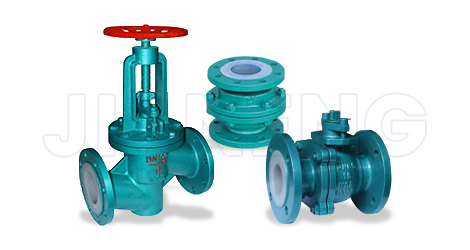

Overview:

Fluorine-lined and rubber-lined valves are composite structure valves with a layer of corrosion-resistant non-metallic material (fluoroplastic or rubber) lining the inside of a metal valve body (such as cast iron, carbon steel, or stainless steel), forming a "metal base + corrosion-resistant lining".

Nominal diameter: 10mm - 1000mm and 1/2" - 60"

Nominal pressure: 1.0MPa to 16.0MPa/150Lb to 1500Lb/10K to 160K

Temperature: -196℃ to 700℃

Standards: GB, DIN, API, ANSI, JIS, BS, etc

Body material: carbon steel, stainless steel, alloy steel, ultra low carbon stainless steel, titanium alloy, high nickel alloy and Monel alloy, etc

Drive methods: manual, worm gear drive, bevel gear, electric, pneumatic, hydraulic, etc

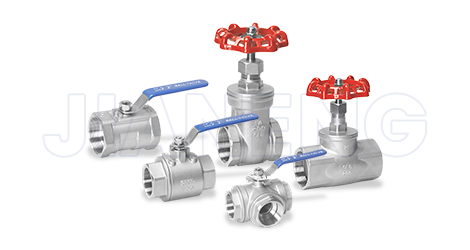

Overview:

Threaded valves (threaded valves) generally refer to threaded valves, which are a type of valve accessory. They mainly refer to valves with internal or external threads on the valve body, which are connected to the pipeline by threads. Valves with threaded connections are usually used in projects with normal low pressure.

Nominal diameter: DN15 - DN50

Nominal pressure: 1.6MPa

Suitable media: water, oil, gas

Standards: GB, DIN, API, ANSI, JIS, BS, etc

Body material: carbon steel, stainless steel, alloy steel, ultra low carbon stainless steel, titanium alloy, high nickel alloy and Monel alloy, etc